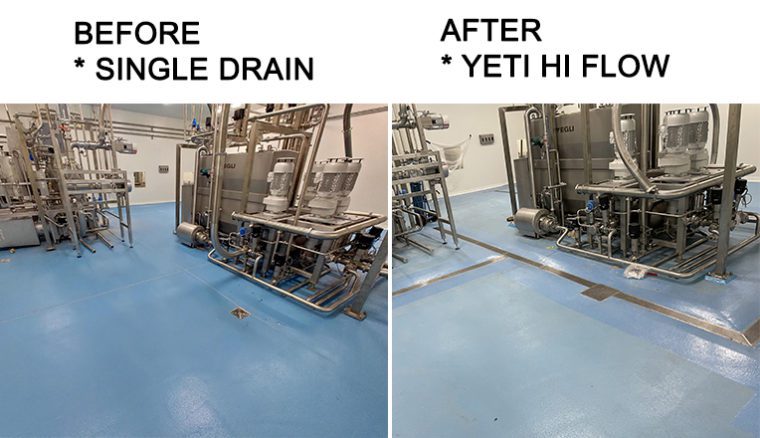

Yeti Civil Products was invited to discuss a new renovation project at a busy food production factory in Melbourne. At the existing site, there were only 2 or 3-point drains in each room. During the daily tank clean, the floor was covered in liquid which had to be manually chased into the minor independent drain points. This exercise proved time-consuming and difficult and presented a hygiene challenge. The following points were extremely important to this project:

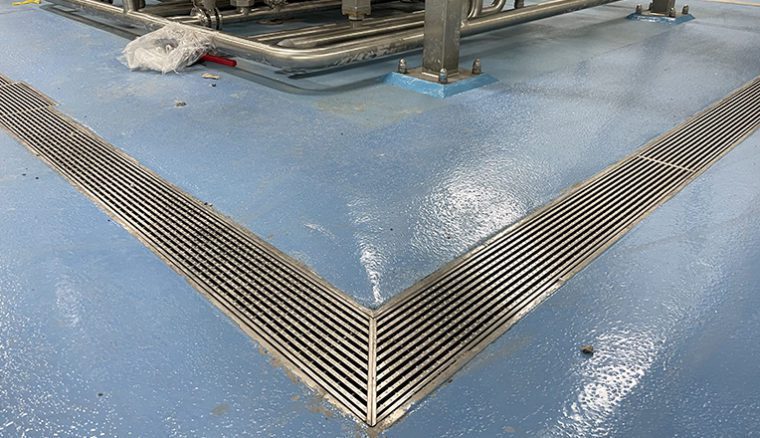

- Drainage layout to efficiently drain away liquid from the surrounding floor

- Built-in fall for rapid discharge of liquids in drain and prevention of ponding in drain base

- SS316 for corrosion resistance against alcohol-based cleaning solutions

- Sealed joints between channel sections for hygiene

- Rapid installation for a tight installation schedule

With further discussions and consultation, our High Flow system was chosen in 100% marine grade, SS316 stainless steel. Our client opted for a 100mm wide clear opening system. As some channel depths exceeded 200mm, we went with bolted gasket connections with chemical-resistant, profile-cut sealing plates.

Our planning team met the client and the subcontractor installers on-site before manufacturing the drainage system. As in this case, the Yeti Hi Flow system was being retrofitted into an existing factory; we followed our retrofit design plan:

- CAD the existing floor plan

- Walk around the floor plan with the client and identify the ideal location of the channel runs

- CAD our drainage design and overlay our drainage design over the existing floor plan

- Check with manufacturing to ensure that the system design is achievable

- Visit the site with our drainage plan and markup the floor ready for site cut

- Subcontractor cuts floor to suit drainage design

- The crushed rock base is compacted into the cutout

- The drain is delivered to the site, and the plumber sets up and plumbs in

- Concretor concretes the drainage system into position

- The epoxy flooring contractor finishes off and seals the flooring up to the drain edge