Stainless steel is a popular material used in many industries, including construction, automotive, and food processing. Choosing the correct grade of stainless steel ensures a project succeeds and meets the desired requirements. Two of the most commonly used grades of stainless steel are 304 and 316.

Stainless steel is a popular material used in various industries, including construction, automotive, medical, and food processing. It is known for its corrosion resistance, durability, and aesthetic appeal. However, not all stainless steel grades are created equal. But which quality is better for the projects in mind? Here are some ideas.

1. Durability

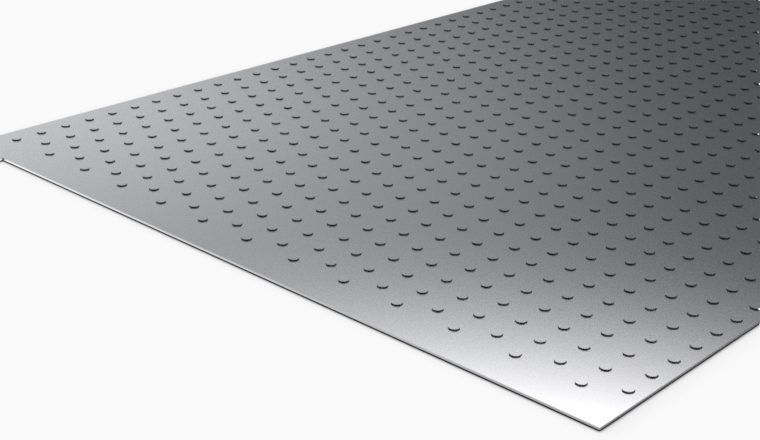

Both 304 and 316 stainless steel are highly durable and corrosion-resistant, making them suitable for matting systems. However, 316 stainless steel has a higher resistance to corrosion than 304 stainless steel, particularly in harsh environments or when exposed to saltwater.

Matting systems made from 316 stainless steel will likely last longer and require less maintenance than those made from 304 stainless steel. Therefore, maintaining and repairing the matting systems will also ensure lesser costs.

2. Affordability

One of the main differences between 304 and 316 stainless steel is their cost. 304 stainless steel is generally less expensive than 316 stainless steel, making it a more affordable option for matting systems. However, this cost difference may be offset by the longer lifespan of 316 stainless steel in harsh environments or when exposed to saltwater.

3. Popularity

Both 304 and 316 stainless steel are widely used in many different industries, including the matting industry. However, 304 stainless steel is more commonly used than 316 stainless steel due to its lower cost and good corrosion resistance. It may be easier to find 304 stainless steel matting systems than those made from 316 stainless steel.

4. Temperature

Another essential factor to consider when choosing between 304 and 316 stainless steel for matting systems is the temperature at which they will be used. 316 stainless steel has a higher melting point than 304 stainless steel, making it suitable for high-temperature environments. This means that matting systems made from 316 stainless steel may be ideal for applications where high temperatures are a concern.

5. Corrosion Resistance

One of the most important factors when choosing a stainless steel grade for matting systems is its corrosion resistance. Both 304 and 316 stainless steel are highly resistant to corrosion, but 316 stainless steel has a higher resistance to corrosion than 304 stainless steel. It is better for matting systems exposed to harsh environments or salt water.

Which Projects Should Use the 304 and 316 Stainless Steel Grade?

304 stainless steel is a good choice for matting systems in indoor or low-corrosion environments, such as office buildings, schools, and residential buildings. It is also suitable for matting methods in food processing and medical facilities.

316 stainless steel, on the other hand, is a better choice for matting systems used in harsh environments, such as outdoor areas exposed to salt water, industrial facilities, and marine applications. It is also suitable for matting methods used in high-temperature environments.

Conclusion

Choosing the correct grade of stainless steel ensures that a matting system is durable, long-lasting, and meets the desired requirements. Both 304 and 316 stainless steel are commonly used in the matting industry. However, 316 stainless steel has higher corrosion resistance and is more suitable for use in harsh environments or when exposed to saltwater.

However, 304 stainless steel is more affordable and widely used, making it a more practical option for some applications. Ultimately, the choice between 304 and 316 stainless steel will depend on the specific requirements of the matting system and the conditions in which it will be used. Ask for an expert opinion before purchasing for various projects.

Looking for high-quality curved steel drains, metal drainage grills, or slot drain solutions in Australia? Look no further than Yeti Civil Products! Our team of experts specialises in providing premium stainless steel trough and grate solutions built to last. Contact us today to learn more about our products and services, and experience Australia’s best stainless steel drainage solutions!